The Future of Manufacturing: 3D Printing in Factories and Robotics in Fast Food

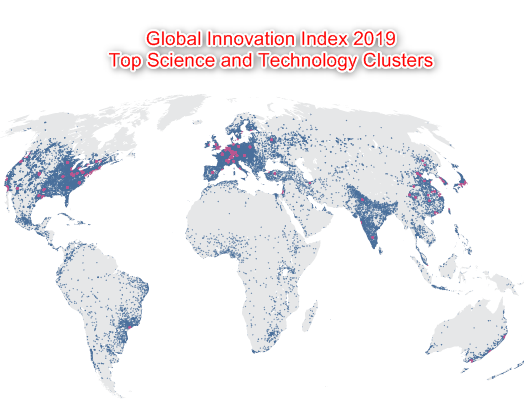

Despite the increasingly digital nature of our world, manufacturing still drives economic productivity across the globe. Statistics published by the World Bank show that the economic value added to world economies by manufacturing rose from $5.77 trillion in 2001 up to $16.38 trillion in 2022. While tech companies and e-commerce giants are making headlines, the strength of a company’s manufacturing sector remains a critical indicator of economic prosperity.

Many customers come to SHIP Global IP because we’re able to provide a personalized touch with a close network of IP management professionals. However, we also provide a sophisticated knowledge of industry trends formed from decades of experience in diverse fields, helping us understand the issues our customers are navigating day to day. In the manufacturing sector, we’ve noticed several emerging technologies that are transforming fabrication processes by reducing waste and costs while producing components with increasingly complex designs.

Second Wave of 3D Printing Companies Benefit from Better Consumer Understanding

A lot of excitement about the 3D printing industry developed in the first half of the 2010s, but many companies pushing the first wave of home 3D printing equipment were unable to capitalize on the early momentum. Companies like MakerBot and 3D Systems, which had envisioned widespread 3D printer use by consumers at home, slashed employee levels and shuttered production facilities by 2015. While some leaders in the industry drew analogies to the early days of personal computers, additive manufacturing technologies did not saturate the home market.

Today, about 15 years after 3D printers first began to hit consumer markets, a second wave of additive manufacturer developers have been building a stronger foundation for themselves. Recent data published by consulting company McKinsey indicates that in 2020, the global additive manufacturing industry was worth $17.2 billion and was set to rise at a 22 percent annual growth rate. The current state of 3D printing technology supports more industrial applications in aerospace, medical devices and other industries that value durable, lightweight components often constructed to unique specifications.

The current generation of 3D printing companies owes a debt of gratitude to the first wave of pioneers that introduced the world to the potential of low-waste manufacturing. Consumers and investors alike have come to better understand the sector and its value. Still, more realistic expectations on the proper consumer base for additive manufacturing has been a more successful strategy for today’s innovators.

Advanced Robotics Will Automate Assembly Lines in Consumer-Facing Industries

The use of robotics to automate fabrication processes have also helped manufacturing companies experience large gains in productivity while keeping costs low. Not only do properly designed robotics eliminate most human errors, but they can also work in environments that human employees cannot, helping manufacturers save even more on climate control and factory lighting. In 2023, the global industrial robotics industry was set to reach $142.8 billion in value and grow at a compound annual growth rate (CAGR) of 11.4 percent over the next decade.

New robotics platforms are finding more industrial applications than traditional manufacturing. American e-commerce giant Amazon.com has been increasingly using robotics systems in its fulfillment warehouses for the better part of a decade. Last November, the company announced that it had developed a new robotics system called Sparrow, Amazon’s first fulfillment robot capable of detecting and handling individual products thanks to improvements in artificial intelligence and computer vision. In the press release, Amazon noted that its robotics-assisted warehouses helped the company ship 5 billion packages in 2022.

Increasingly, robotics are also finding their way into consumer-facing industries like fast food. Labor shortages led fast casual restaurant chain Chipotle partnered with Vebu Labs to develop the Autocado, a robotics system designed to cut, core and peel avocados. This automates one of the more time-consuming tasks for back-of-house Chipotle employees, although humans will still be involved in making guacamole from the processed avocados. This robotic form of guacamole production represents how automation has been branching out from the traditional manufacturing sector to become a more noticeable part of a consumer’s daily life.

Injection Molding Takes On New Focus in Additive Manufacturing Operations

Injection molding, or the process of fabricating products by pouring molten plastic into a mold to set, is not a new technology. The American industrial boom during the first half of the 20th century made heavy use of injection molding processes, and manufacturing companies that have to produce high volumes of standardized components continue to utilize molding operations in their production lines.

While 3D printing is capable of producing complex and highly customized components, injection molding offers another low-waste form of fabrication that some companies are using in tandem with their other additive manufacturing solutions. Many companies find that 3D printing is more useful during the prototyping process, when development teams have to tinker with product designs. Using these techniques, many companies are able to reduce their product development process by weeks. When it’s time to ramp up production, that’s when manufacturing companies turn to injection molding to quickly produce large quantities of parts.

The current generation of 3D printing companies are also pushing advances in injection molding materials as well. Recently, additive manufacturing materials company CRP Technology announced that it had released an injection molding-grade form of its Windform XT 2.0 IMG formulation that retains the high-level stiffness and shock resistance exhibited by the Windform formulation in laser sintering operations.

Final Takeaways for the Manufacturing Sector of Tomorrow

For companies operating in manufacturing fields, there are a few clear takeaways from these trends. Investing in R&D related to robotics and 3D printing is critical for future success. Further, the boundaries of traditional manufacturing have been blurring. While 3D printers themselves may never take hold in consumer homes, many people are getting more comfortable with the concepts of additive manufacturing and automation in their daily lives.